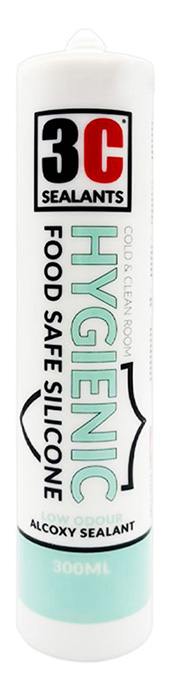

HYGIENIC

FOOD SAFE SILICONE

Well priced - Certified reliable sealant

Food safe - Specially made for food contact

Low odour cure - for enclosed areas

Versatile use - Factories, restaurants & hospitals

3C HYGIENIC FOOD SAFE COLD & CLEAN ROOM SILICONE SEALANT - COLOUR

-

Snow White

CRAIG PHILLIPS (from MR AND MRS DIY)

3C HYGIENIC FOOD SAFE SILICONE SEALANT FAQ's

In general, you’d use a sanitary sealant, (i.e. a high modulus silicone or polymer with an fungicide) in an environment where high humidity, moisture, warmth, and/or organic contamination create a high risk of mould or bacterial growth, this is pretty much all areas where steam is intermittent and running or standing water is prevalent such as bathrooms, kitchens and spa areas.

When considering whether a standard sanitary silicone sealant should be used versus when a specialist hygiene sealant should be considered, some key points are worth taking into account.

1. Biocidal Protection (Primary Difference)

Hygiene silicone contains fungicides and bactericides that actively inhibit:

-

Black mould (Aspergillus, Cladosporium)

-

Mildew

-

Biofilm formation

Standard silicone does not contain sufficient long-term biocidal additives. In wet areas, mould will colonise the surface within months.

Result:

Hygiene silicone maintains a clean joint significantly longer.

2. Long-Term Performance in Wet Environments

Hygiene silicones are engineered for permanent water exposure, including:

-

Bathrooms (showers, baths, basins)

-

Kitchens (sinks, worktops)

-

Healthcare and food-prep environments

They maintain:

-

Elasticity

-

Adhesion

-

Colour stability (less yellowing or staining)

Standard silicones may technically be waterproof, but they degrade faster when exposed to detergents, soaps, and heat cycles.

3. Compliance & Use in Regulated Spaces

Many hygiene silicones meet or align with:

-

EN 15651-3 (XS1 / XS2) – mould resistance classification

-

Food-safe or low-VOC requirements (product-specific)

This makes them suitable for:

-

Hospitals

-

Care homes

-

Commercial kitchens

-

Laboratories

Standard silicone typically fails to meet these hygiene classifications.

4. Surface Chemistry & Cleanability

Hygiene silicones often have:

-

A smoother cured surface

-

Lower surface energy that resists dirt adhesion

-

Better resistance to aggressive cleaning agents

This reduces:

-

Staining

-

Soap scum build-up

-

Bacterial harbouring at the joint line

5. Lifecycle Cost (Often Overlooked)

Although hygiene silicone costs more upfront:

-

It lasts longer before discolouration or failure

-

Requires fewer replacements

-

Reduces maintenance labour

Net effect: lower total cost of ownership in wet areas.

When Standard Silicone Is Acceptable

Standard silicone is fine for:

-

Dry interior joints

-

Decorative sealing

-

Low-humidity areas

-

Temporary applications

It is not appropriate for constantly wet or hygiene-critical zones.

Summary

Use hygiene silicone when:

-

Moisture is persistent

-

Mould resistance matters

-

Cleanability and compliance are required

Use standard silicone when:

-

The joint is dry

-

Appearance is short-term

-

Hygiene performance is non-critical

If you want, I can also break this down by bathroom vs kitchen vs healthcare use, or compare neutral-cure vs acetoxy hygiene silicones.

Answer to follow

Answer to follow

Still have questions about Hygienic Food Safe Silicone?

BUY MORE SAVE MORE 3C HYGIENIC FOOD SAFE COLD & CLEAN ROOM SILICONE SEALANT

1-9 x Carts

From

- Snow White 300ml

25-1199 x Carts

From

- Snow White 300ml

10-24 x Carts

From

- Snow White 300ml

1200 x Carts

From

- Snow White 300ml

REASONS TO BUY 3C HYGIENIC FOOD SAFE SILICONE COLD & CLEAN ROOM SEALANT

3C HYGIENC FOOD SAFE SILICONE APPLICATION IDEAS