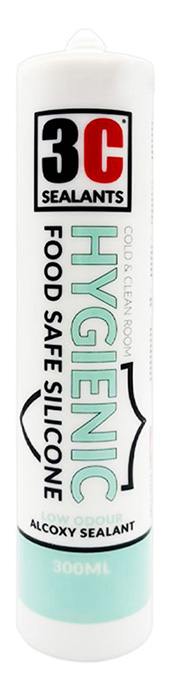

HYGIENIC

FOOD SAFE SILICONE

Well priced - Certified reliable sealant

Food safe - Specially made for food contact

Low odour cure - for enclosed areas

Versatile use - Factories, restaurants & hospitals

3C HYGIENIC FOOD SAFE COLD & CLEAN ROOM SILICONE SEALANT - COLOUR

-

Snow White

CRAIG PHILLIPS (from MR AND MRS DIY)

3C HYGIENIC FOOD SAFE SILICONE SEALANT FAQ's

In general, you’d use a sanitary sealant, (i.e. a high modulus silicone or polymer with an fungicide) in an environment where high humidity, moisture, warmth, and/or organic contamination create a high risk of mould or bacterial growth, this is pretty much all areas where steam is intermittent and running or standing water is prevalent such as (but not exclusively) bathrooms, kitchens and spa areas.

When considering whether a standard sanitary sealant should be used versus when a specialist hygiene sealant should be considered, some key points are worth taking into account for each individual application.

The primary difference is normally anti-bacterial biocidal protection. Whereas standard sanitary sealants contain anti-mould fungicides, specialist hygiene sealants also contain biocidal bactericides that actively inhibit bacteria-based nasties such as black mould (Aspergillus, Cladosporium), mildew, biofilm formation and various food poisoning bugs.

Standard sealants do not contain sufficient long-term biocidal additives so, in permanently damp or wet areas, mould will colonise the surface within months.

Standard sealants are normally waterproof to a point but they will almost certainly degrade faster when exposed to bleach, detergents, soaps and changing temperature cycles.

As well as being armed with specialist biocides, 3C Hygienic Food Safe Silicone Cold & Clean Room Sealant is a specialist hygiene product engineered for long-term performance primarily in bathrooms, kitchens, healthcare and food preparation/serving environments, compared to standard internal high modulus sealants, it better maintains:

Elasticity

Adhesion

Colour stability (less yellowing over time)

To summarise why or when you should use a hygienic silicone as opposed to a standard sanitary silicone in cold rooms, clean rooms and/or environments where food is prepared or served;

If considerable moisture is persistent

For superior longevity of mould resistance

If perfect cleanability is required

If certified compliance is required

As detailed above, specialist hygiene-specific sealants such as 3C Hygienic Food Safe Silicone Cold & Clean Room Sealant can technically be used in any internal area where humidity is apparent and anti-mould fungicide is necessary but it may be overkill for most basic applications.

The main point of such a unique sealant product is to seal connection joints and gaps in environments where contact with food is likely and/or improved health protection is a major consideration as they adhere to strict hygiene rules, have superior cleanability and contain microbial resistance.

As well as in residential properties, 3C Hygienic Food Safe Silicone Cold & Clean Room is certified and adequately suitable for use in commercial, industrial and agricultural sectors alike. Below is a list of some examples:

Food & beverage environments

Food processing plants

Commercial kitchens and catering facilities

Breweries, dairies, bottling and packaging lines

Cold rooms and clean food storage areas

Used around: stainless steel worktops, wall–floor junctions, drains, splashbacks, machinery interfaces.

Healthcare & pharmaceutical

Hospitals and clinics

Operating theatres

Laboratories and cleanrooms

Pharmaceutical manufacturing facilities

Used where infection control is critical: washrooms, scrub areas, medical equipment junctions.

Sanitary & washroom areas

Showers, wet rooms, toilets, changing rooms

Care homes, schools, gyms, hotels

Especially important at: tile joints, wall–floor transitions, around basins, WCs, and shower trays.

Clean manufacturing & high-care areas

Electronics cleanrooms

Cosmetic manufacturing

Veterinary facilities

Most hygiene specific sealants (such as 3C Hygienic Food Safe Silicone Cold & Clean Room Sealant) meet or align with safety standards, where standard sanitary sealants typically fail to meet these hygiene classifications for example:

EN 15651-3 (XS1 / XS2) – mould resistance classification

Food-safe or low-VOC requirements (product-specific) (meets FDA code 21 §177.2600 (e))

Low odour - for enclosed areas whilst curing

Anti-mould formulation

High resistance to UV

Permanently elastic

High resistance to high & low temperatures

Very easy to apply and tool

Excellent adhesion to most building substrates

This makes hygienic sealants fully certified and legally suitable for sealing gaps and joints in officiated areas such as:

Hospitals

Care homes

Commercial kitchens

Laboratories

Some reasons why this could matter when designing, specifying and maintaining these environments are lower surface energy that resists dirt adhesion and better resistance to aggressive cleaning agents (to reduce staining, soap scum build-up and bacterial harbouring at the line of the joint).

With the above in mind, an often overlooked cost comparison when compared to inferior, non-specific products is the actual lifecycle cost. Although specialist hygiene sealants (such as 3C Hygienic Food Safe Silicone Cold & Clean Room Sealant) tend to cost slightly more upfront, they last longer before discolouration or failure require less frequent replacement which, of course, reduce maintenance labour over time.

Still have questions about Hygienic Food Safe Silicone?

BUY MORE SAVE MORE 3C HYGIENIC FOOD SAFE COLD & CLEAN ROOM SILICONE SEALANT

1-9 x Carts

From

- Snow White 300ml

25-1199 x Carts

From

- Snow White 300ml

10-24 x Carts

From

- Snow White 300ml

1200 x Carts

From

- Snow White 300ml

REASONS TO BUY 3C HYGIENIC FOOD SAFE SILICONE COLD & CLEAN ROOM SEALANT

3C HYGIENC FOOD SAFE SILICONE APPLICATION IDEAS